Introduction

Khadi, also known as Khaddar ,which started as a symbol of the Swadeshi Movement led by Mahatma Gandhi 100 years ago, is now a fashion statement in India and is gradually getting popular across the globe. Not only as an affordable and comfortable fabric for daily-wears, but also Khadi is now being considered as a Style Statement for its sustainability and eco-friendliness.

Nature of The Khadi Material

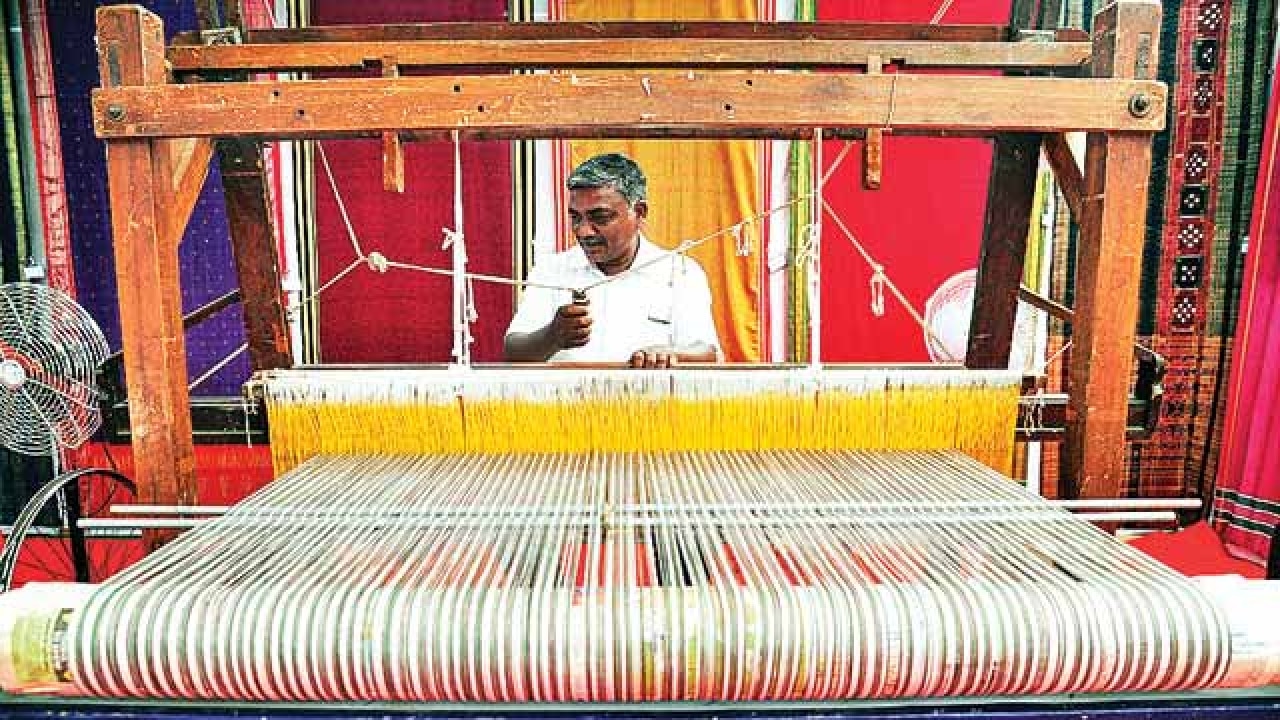

Khadi is a textile fabric made by hand-spun and hand-woven cotton, silk, wool or a mixture of these fibres. It is a traditional way of textile manufacturing and is generally produced by rural artisans. The method of manual spinning and weaving makes the fabric structure somewhat rugged and imparts a unique appearance and makes it soft and comfortable to wear. The spinning is carried out on a traditional wooden frame called charkha, while the weaving is done on a handloom. The specific fabric construction helps in circulation of air within the threads and imparts unique property of keeping the wearer warm in winter as well as cool in summer.

History of Khadi : Role in India’s Freedom Movement

India has an ancient heritage of cloth making based on the availability of natural fibrous raw material such as -agricultural cotton owing to the clement climatic conditions and fertile land, varieties of silk from different sericulture and wool from domestically reared sheep. The textile coloration was carried out using abundantly available natural dyes, derived from various plant and animal extracts. Such flourishing textile base was one of the major attractions for the Western world. After mechanised industrialisation, the situation changed and the basic raw material was exported from India, converted into mill-processed finished cloth and the imported fabric was brought back. This led to the demolition of traditional textile manufacturing in India and eventually the art and craft of fabric making diminished.

During the initial phase of the freedom movement, national leaders like Dadabhai Naoroji and Lokmanya Tilak initiated the Swadeshi Movement to promote Indian-made products. However, it was Mahatma Gandhi who in 1918 brought the focus of India’s freedom struggle to khadi by promoting that as a Swadeshi symbol.

Under the leadership of Mahatma Gandhi, khadi-making regained momentum and became a symbol of revolution and resistance. It also provided employment to the vast rural population of India and achieved distinct identity as a common man’s cloth. As everybody could wear the same form of clothing without any distinctions of class, creed or religion, they could demonstrate solidarity in freedom struggle. Wearing khadi became a matter of national pride and united the population of India by surpassing the divisive system of the region, language, religion, caste, age and gender. It reflected our country’s legacy of sustainable living and self-reliance. The Indian national flag is also made from khadi material.

Government Initiatives After India’s Independence

The Khadi and Village Industries Commission (KVIC) is the Indian government body that promotes khadi, whose production and sale comes under the small scale industry sector. KVIC was created by a parliament act after which many KVIC outlets were opened across the country. These shops sell khadi fabrics and apparel. Every year between October to January, all Khadi Gramodyog Bhavans offer discounts on their products. KVIC also organises exhibitions and trade fairs in the country and abroad to promote khadi.

An estimated 15 lakh people are now engaged in producing over 12 crore metres of khadi. KVIC is taking further steps to enhance its production as the market demand for such products is much more than the supply. A new programme is expected to establish the ‘Khadi Mark’ and a logo to indicate the genuineness of the product. The financial support provided and the political will exerted by the present government and the special emphasis from Prime Minister Narendra Modi has helped boost employment in the manufacturing and promotion of khadi products. Leading film artists, sports personalities and fashion designers have come forward to promote this unique ‘Made in India’ fabric in the global arena.

Contribution of Khadi in World Fashion

Considering khadi‘s eco-friendly and natural origin, it has become a focal point of global fashion owing to growing consumer awareness and the consistent demand for sustainability. Fashion designers have acknowledged the aesthetic appeal and comfort attributes of khadi and experimented it in blending with many other stuff to synergistically enhance the fashion appeal and outlook of products. Khadi is now used in denims, jackets, shirts, dress material, stoles, home furnishings and apparel accessories like handbags. Khadi, once considered as the fabric for political leaders and the rural folk, has entered the wardrobe of the fashion-conscious urban population. Wearing khadi now symbolises affluence as it offers a distinguished look. The ecological aspect and ethnic looks of khadi have caught the fancy of global brands and leading fashion designers have started including khadi material in their collections.

Conclusion

Incorporating Khadi in our daily life may also pave the way for a simple spiritual living exuded by our clothing and home décor items. Khadi being such a versatile fabric can be easily incorporated, by changing the warp and weft, in a home decor and clothing lines. This will make us come closer to nature and add a touch of earthiness in our lifestyle.

You must be logged in to post a comment.