An electrical system is a network of components that work together to generate, distribute, and consume electrical power. The structure of an electrical system can vary widely depending on the size and complexity of the system. However, there are certain fundamental components that are common to most electrical systems.

Source – https://engineeringnotesonline.com/

Power Source –

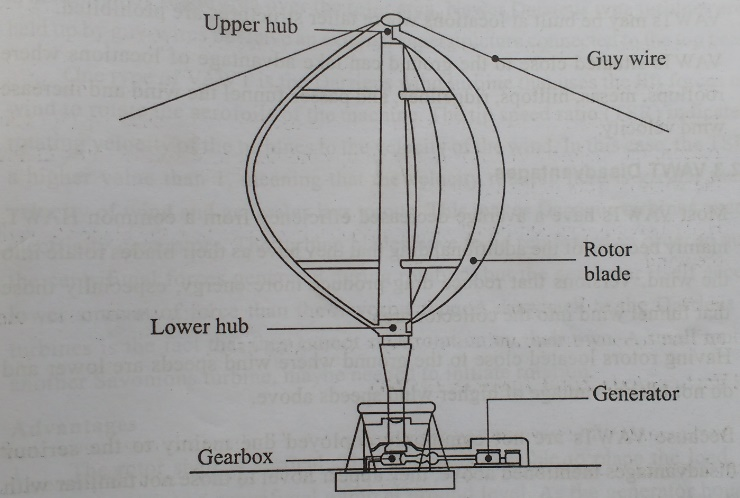

The first component of an electrical system is the power source. This is the device that generates electrical power. It can be a generator, a battery, or a solar panel, depending on the application. The power source is connected to the rest of the system through a set of wires or cables, which carry the electrical power to the other components.

Load –

The next component of an electrical system is the load. This is the device that consumes the electrical power. The load can be a light bulb, a motor, or any other electrical device. The load is also connected to the rest of the system through a set of wires or cables.

Switch –

In between the power source and the load, there are several other components that help to regulate and control the flow of electrical power. One of the most important of these components is the switch. A switch is a device that can be used to turn the flow of electrical power on and off. It is often used to control the operation of a load, such as a motor.

Transformer –

Another important component of an electrical system is the transformer. A transformer is a device that can be used to change the voltage of the electrical power. This is important because different devices require different voltages to operate properly. For example, a motor may require a higher voltage than a light bulb. A transformer can be used to step up or step down the voltage of the electrical power as needed.

Distribution System –

The distribution system is also a crucial component of an electrical system. This is the network of wires and cables that carry the electrical power from the power source to the loads. The distribution system is often divided into several different levels, such as the transmission system, the sub-transmission system, and the distribution system. Each level of the distribution system is designed to handle a specific amount of electrical power and to serve a specific geographic area.

Protective Devices –

Finally, an electrical system may also include various protective devices, such as fuses and circuit breakers. These devices are designed to protect the system from overloads and short circuits, which can damage the components and cause fires or other hazards.

You can read more about protective devices here.